Creating a blend of expertise and locality enables us to cater to a range of applications, and be a solution provider for many spheres of activity throughout the country.

Quick Links

Solutions

©2024 Meatech Solutions. All rights reserved.

Meatech Solutions

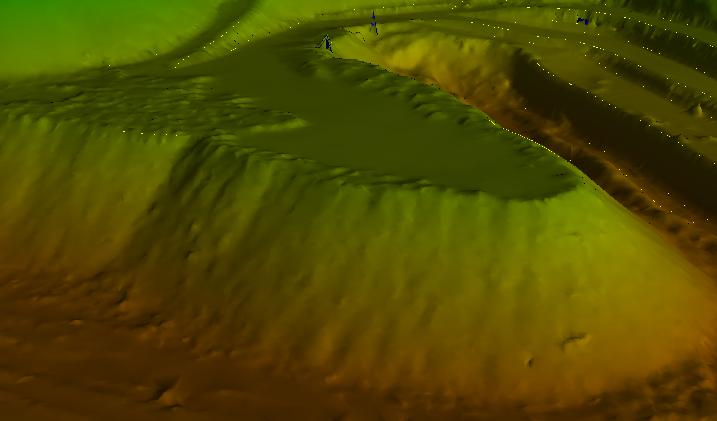

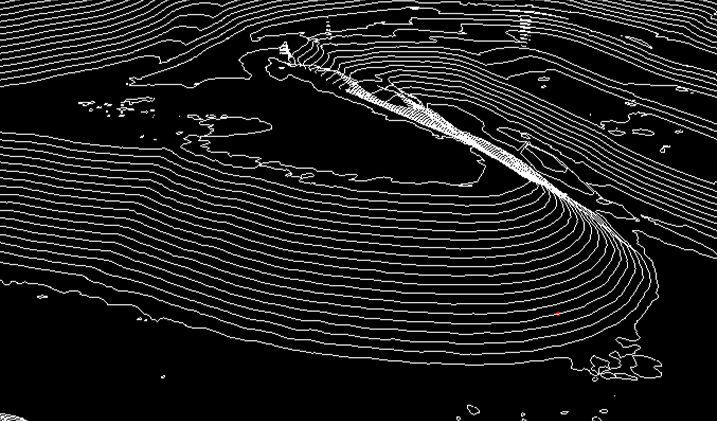

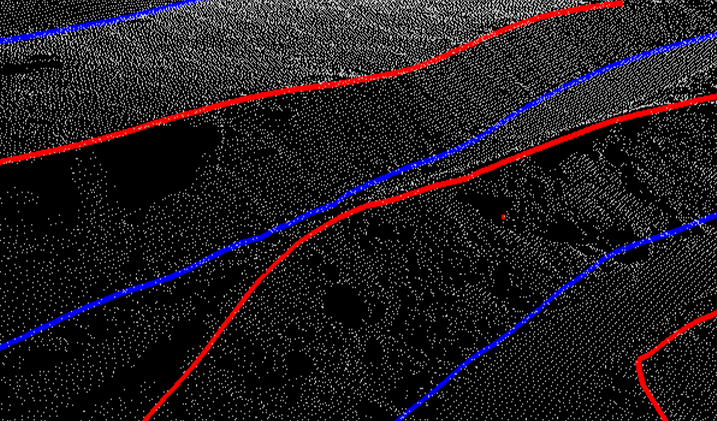

The RIEGL VZ Terrestrial Laser Scanners have cutting-edge 3D LiDAR Scanning Technology. Our 3D Scanners fire rapid pulses of laser light at a surface up to 5,00,000 pulses per second and a sensor inside the scanner measures the amount of time it takes for each pulse to bounce back. By repeating this process very fast, the Scanner builds up a realistic 3-D scenery called as “point cloud” of the Mine.

Our Laser Scanning solutions based on RIEGL 3D Terrestrial Laser Scanner are being used in India for various mining measurement applications such as:

| Range up to 800m | Range up to 2500m | Range up to 4000m |

| 3600 Field of view | ||

| Acquisition of 3-D point cloud with millions of points collected within a minute | ||

| Multiple target capability (Capability to penetrate vegetations up to 15 targets) | ||

| Simultaneous image and scan data acquisition | ||

| Freedom from stationing the scanner over a known point station | ||

| Modes of operations: Onboard standalone qwerty touchscreen/remote control through mobile, laptop and tablets | ||

| Highly accurate and precise data with few millimetres’ accuracy and precision | ||

| Highly effective in collecting data from very low reflective surfaces like coal, soil and glaciers etc | ||

Creating a blend of expertise and locality enables us to cater to a range of applications, and be a solution provider for many spheres of activity throughout the country.

©2024 Meatech Solutions. All rights reserved.

Your cart is empty Continue Shopping