Wind Lidars

Vertical Profiling Lidar onshore-ZX300

Design

ZX 300 (formerly ZephIR 300) is designed for extreme conditions with a small, angled top surface to allow rain and snow to run off easily

Access to data :Your high value wind data is available through a range of communication protocols from Wi-Fi to a direct Ethernet connection and over mobile / cellular networks. On-board Lidar software helps to configure, check status and play live and recorded a timeseries. ZX Complex Flow Solver Deutsche WindGuard accepts the use of standalone ZX 300 wind Lidar in complex terrain using ZX Complex Flow Solver. This tool uses high speed CFD modelling to convert Lidar data in to equivalent met mast data in areas of complex flow. ZX CFS is available as a post-processing tool for complete transparency and audit in project due diligence.

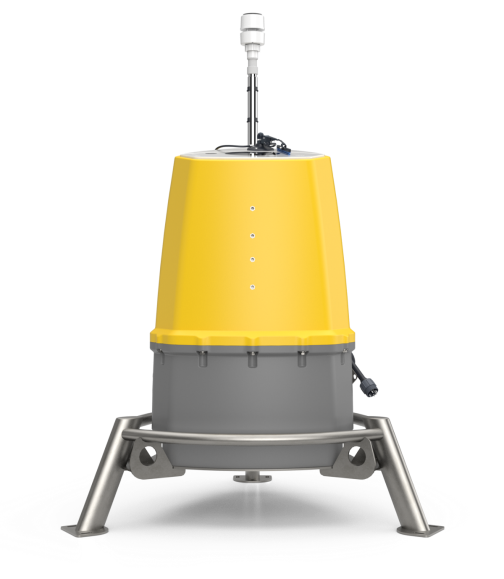

Vertical Profiling Lidar offshore- ZX300M

Wind resource assessment and measurements offshore Responsible for 95%+ of all new offshore wind measurements globally £150bn of finance invested in clean energy from ZX 300M data 10-300m range – the widest range available of any Lidar.

Offshore wind measurements from a vertical profiling Lidar from 10 to 300 meters, fully integrated on all commercially available Floating Lidar Devices. The industry standard offshore, for more than a decade.

We love the motion of the ocean.

From the ruggedised product casing to the inherent system design of a Continuous Wave Lidar we are very much at home at sea. Our Lidars routinely operate for 3 years autonomously in the harsh offshore environment without missing a beat, or a wave, or a data point.

Quality of data:

50 wind measurement points per second optimized for high motion applications offshore

Made to last :

IP69 casing for marine survivability and robustness Small form factor for met ocean buoys.

Tried and tested :

The Use Cases presented here have been tried and tested over the last decade. Lidar users help to inform standards which in turn help to drive change. New Use Cases are being developed all of the time. Benefits are gained throughout a project lifecycle.

Horizontal Wind Lidar, turbine / nacelle-based- ZXTM

Quality of data

Records measurements from 10-550m with high data availability at all ranges 50 wind measurement points per second optimised for Rotor Equivalent Wind Speeds, wakes and full shear and veer measurements Laser focussed at each range for ultra high sensitivity and data recovery.

Tried and tested :The Use Cases presented here have been tried and tested over the last decade. Lidar users help to inform standards which in turn help to drive change. New Use Cases are being developed all of the time. Benefits are gained throughout a project lifecycle.

Access to data : Your high value wind data is available through a range of communication protocols from Wi-Fi to a direct Ethernet connection and over mobile / cellular networks. On-board Lidar software helps to configure, check status and play live and recorded a timeseries.

Lidar frame design for wind turbines : Our Engineering team can provide bespoke designs of Lidar frame to suit any onshore or offshore wind turbine. ZX TM is extensively used within the industry and we often have bespoke designs already available and approved by the WTG OEM for use.